Industrial fireproofing is critical for safeguarding property and people. Protecting the structural components of a building during a fire is crucial, making fireproofing an essential aspect of construction.

Why do buildings need to be fireproofed?

Why you’d fireproof a building may seem obvious, but here are three of the most essential reasons:

Compliance with safety regulations and practices

It’s important for property owners to have knowledge of the safety regulations for both commercial and residential buildings. Many buildings that catch fire aren’t compliant with National Fire Protection Association and Occupational Safety and Health Administration standards.

Increase the resistance of fire

Whether it’s in the building materials or structural form, fire resistance measures during the construction of buildings is vital. Known as passive fire protection, these help preserve life and property in a fire outbreak.

A fire can start and quickly spread to other areas of the buildings by igniting the easily combustible substances nearby. This can lead to the collapse of the structure.

Measures like using non-combustible materials and fireproofing a building during construction slows down the duration and speed a fire spreads.

Safeguarding critical control systems and keeping them operational

Every minute and second counts during a fire emergency. This is why critical control systems and emergency equipment must be adequately maintained, identified, and located. They should be in easily accessible areas and away from the source of hazard.

Emergency devices and warning lights should be located in conveniently reachable places, far from any potential danger. Regular inspection, testing, and maintenance of these devices are crucial to guarantee safety.

TOP 4 MATERIALS FOR INDUSTRIAL FIREPROOFING

When a fire reaches approximately 1000°F, the design integrity of structural steel diminishes by approximately 50%.Using fireproofing material delays the time taken for a fire to reach its average burning temperature of 1800°F – 2000°F.

Standards and design guidelines don’t explicitly recommend a specific fireproofing material. Nevertheless, it’s essential that the material used is constructed from a long-lasting and resistant substance to both corrosion and wear.

Let’s take a look at the top 4 materials you should consider using for industrial fireproofing.

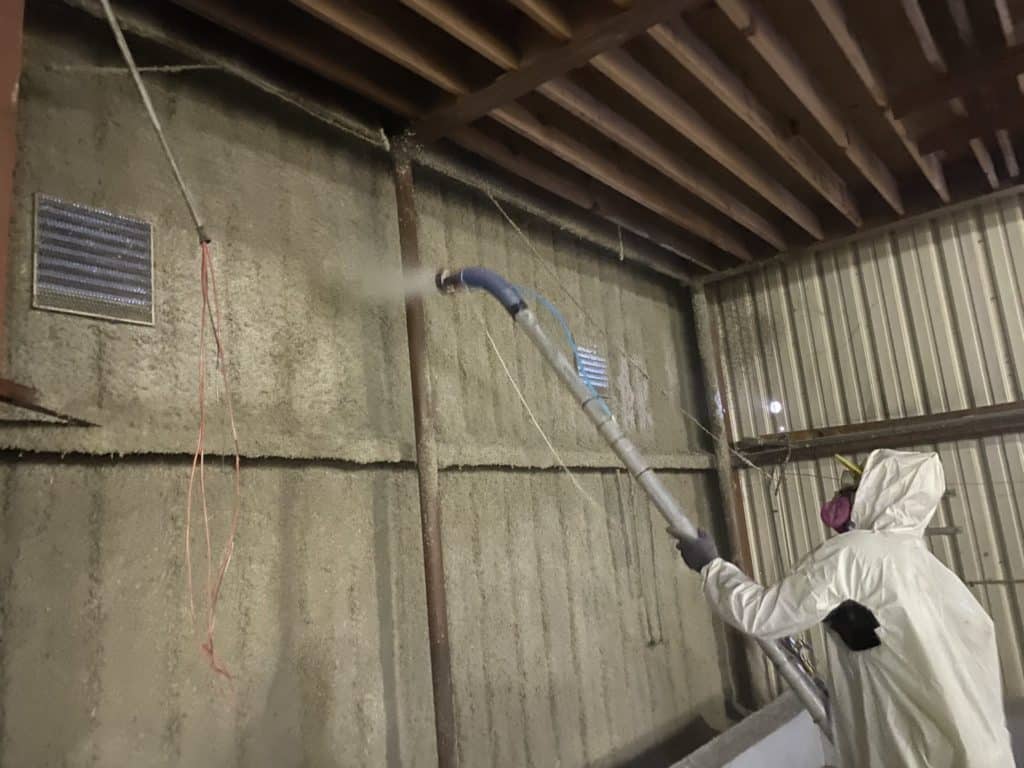

1. SPRAY FOAM FIREPROOFING INSULATION

If you’re seeking a highly efficient fireproof insulation option that is also non-toxic, spray foam is your solution. Not only does it have fire retardant properties, but it’s also self-extinguishing. Furthermore, it occupies all voids requiring effective insulation, thus creating a barrier against heat dissipation.

Unlike traditional insulation materials, like gypsum or cement fiberboard, spray foam doesn’t release toxins into the air as it deteriorates.

Also called Spray Applied Fire-Resistive Material or Sprayed Fire-Resistive Material, it complies with fire safety building codes and regulations. Because it’s self-extinguishing, spray foam allows the fire to be contained, and the flames don’t fully take hold.

APPLICATION: There are three types of spray foam insulation: low, medium, and high-density. First, a powder mixture is integrated with water to form a cement-like substance. Then, it’s uniformly applied directly onto steel structures using a high-pressure spraying method.

2. FIBROUS PLASTER: WOOL OR FIBERGLASS

Fiberglass is a fireproof material that is resistant to moisture and non-combustible. It’s created by combining extremely thin strands of glass. Then, a specially formulated resin is applied to act as a binding agent.

Fiberglass is a great choice for both residential and commercial buildings due to its availability, affordability, and effectiveness. Although it’s not completely fireproof, it can withstand high temperatures of up to 1220°F.

Mineral wool, also known as glass or rock wool, is another type of non-combustible insulation that is highly effective. It’s often combined with other forms of insulation to enhance its fire resistance rating.

APPLICATION: It’s important to be careful when cutting and measuring fiberglass. Tiny slivers of glass can break away and harm your eyes and skin if you don’t have proper safety equipment. To ensure safety, employ a staple gun to fasten the insulation cutout onto the wall framing.

3. INTUMESCENT COATING

Using fire-resistant materials on walls helps stop fire from spreading and protects people and property. This is the idea behind intumescent fireproofing.

Intumescent coating stops fire from spreading in a building by expanding and absorbing heat when it touches high temperatures. The reaction forms a spongy foam that efficiently reduces the rate at which heat moves from the fire to the underlying surface.

APPLICATION: Intumescent paint is a spray applied fireproofing used as a base layer directly on the surface. It can be used on a range of applications, including steel elements, timber, concrete, and composites.

4. CEMENTITIOUS COATING

Cementitious fireproofing is a protective coating applied to structures to enhance their resistance to fire and heat. Composed of cement, aggregates, and special additives, the mixture forms a thick layer that acts as a barrier. It insulates the underlying structure from extreme temperatures.

It helps prevent the structural elements from weakening too quickly and maintains their integrity. This gives people more time to evacuate and firefighters a better chance to control the situation.

APPLICATION: Applying cementitious fireproofing involves a systematic process. First, the surface is prepared by cleaning it of dirt, dust, and any loose materials. Then, the mixture is prepared, ensuring the right consistency. The mixture is sprayed onto the surface using specialized equipment.

In Summary

There’s a wide range of materials available to make residential, commercial, or industrial buildings resistant to fire. To ensure the best results, it’s important to collaborate with a licensed contractor.

At Sunlight Contractors, we’re able to offer recommendations regarding the most effective material for your specific construction needs.