Why Choose Sunlight?

For over 18 years, Sunlight Contractors has served the spray foam insulation, mold testing & remediation, fireproofing, renovations, and soundproofing needs of homeowners and businesses in all of Louisiana. Make sure when choosing a spray foam contractor to make sure they are licensed and certified with the LSLBC. You always want a contractor that is backed by licensure and certifications for your peace of mind.

With 1000+ five-star reviews, Sunlight Contractors is the most trusted installer of spray foam insulation in NOLA.

Contact Us For A Free Quote

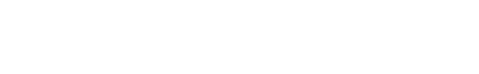

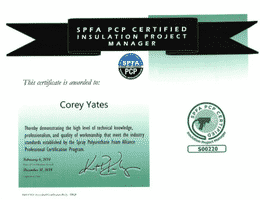

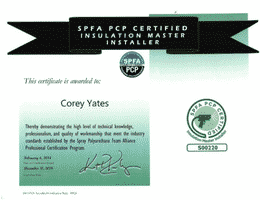

Our Spray Foam Installer Credentials

This identification card must be carried by the Certified Individual at all times when installing SPF. The Assistant and/or Installer must be supervised by a Master Installer or Project Manager at all times.

The Individual named on this card agrees to abide by all directives issued by SPFA and to perform all installations in accordance with the requirements outlined in the certification agreement and the SPFA PCP Certification Handbook.

This card is property of the SPFA PCP and shall be returned upon request. For verification call SPFA-PCP 1-866-222-5000. F-222-020 rev 1 (06/23/14)

Why Install Spray Foam Insulation?

Air moves in and out of a home through every hole, crack, and crevice. Roughly one-third of air infiltrates through walls, ceilings and floors. Adding an advanced insulation system is necessary to achieve optimal building performance. Spray Foam is that advanced insulation system.

Spray foam insulation can maximize a homeowner's investment by sealing the building envelope to stop conditioned indoor air from escaping and prevent unconditioned air from entering a home. Additionally, proper insulation can increase home value.

Air exchange in and out of a home is a leading cause of escalated energy bills. The mechanical systems that heat and cool buildings are continuously operating; reducing extreme temperature variations saves on the overuse of mechanical systems and leads to lower energy bills.

The Benefits of Spray Foam Insulation

Reduces utility costs

Prevents energy waste

Increases comfort

Eliminates Air Loss

Improves Air Loss

Improves Indoor Air Quality

Maintains Consistency Over Time

Strenghtens Structures

R-Value Matters

Closed-cell foam has the highest spray foam R-value of any insulation material available, at up to R6.8 per inch (the higher the R-value of a material, the greater its resistance to the movement of heat). Open-cell spray foam has an R-value average of R-3.7. Using thermal imaging cameras with a blower door, it’s not uncommon to see missing pieces of fiberglass insulation or a two-inch gap between batts where heat can be lost. With a monolithic seal of spray foam that is not going to happen.

Space Savings

Spray foam takes up much less space than fiberglass or blown-in cellulose. Its thickness depends on where it’s applied, but it averages about 5”-6” deep once installed for open cell spray foam. Closed cell spray foam is 2”-3” thick depending on your requirements.

Energy Savings

With an energy-efficient HVAC system, you can see savings of up to 40 percent or more if your house is re-insulated with spray foam properly. This means that the initial spray foam insulation cost can be more than offset by the savings on your energy bills.

We are a SPFA Certified Contractors

- We are proud distributors of SES Sucraseal Open Cell Foam

- Gaco OnePass 2lb Closed Cell Spray Foam

- Gaco Western 3lb Gaco Roof Foam

- Gaco Silicone S4200 – 10, 15, or 20 year warranty

- Fireproof coating DC 315

- CAFCO Blaze – Shield fire resistant coatings

- K-13 acoustical and thermal solutions – sporting event centers

- Applegate Cellulose Insulation

What room is right for spray foam?

Closed cell spray foam is used for your wooden substrate under your home. (Subfloor/Crawlspace). Closed cell spray foam is an effective air barrier, thermal barrier, and moisture barrier, and provides the best insulation and soundproof qualities for under the home, and in the walls.

Open cell spray foam is mainly for the attic. It seals off the cracks and leaks from the inside and provides a thermal barrier and air barrier. It will likely bring down the humidity and condensation in your home, and not be affected by the outside air making your home a conditioned space.

We Only Send Certified Contractors

Our Locations

Servicing all of Louisiana – Including Metairie, Marrero, Harvey, Mandeville, LaPlace, Norco Covington, Gretna, Destrehan, Lacombe, Saint Rose, Madisonville, Baker, Slaughter, Zachary, Bay St. louis, Picayune, Diamondhead, and more. Call (504) 919-9993, or any of our locations for more information on your service area!